OLED TV technology is one of the most exciting developments in home cinema in recent memory, c ombining the very best of plasma and LED in one fell swoop. Without the need for a backlight, it's able to produce richer, more vibrant colours than current LCD sets, super deep blacks, excellent viewing angles and a high contrast ratio - better than even plasma managed. Yet, for all the talk about it being the holy grail of TV tech, few manufacturers have actually managed to make it a viable option for the typical living room.

This is partly due to the complicated process of making OLED panels, particularly in large screen sizes. Due to long manufacturing times, this makes it an incredibly costly venture, with some current OLED TVs costing upwards of £2,000 for 55in sets and an eye-watering £20,000 for 77in sets.

However, LG may finally have a solution to at least the production part of the problem, as the company has told Expert Reviews that it's now in the position to rapidly increase its OLED TV production thanks to new advancements it's made in the way it develops its OLED panels.

"There are three main technologies behind OLED TV production," explains Brian Han, OLED Promotion Manager for LG Displays. "First there is the TFT backplane technology, which controls the electric signals of each pixel. Second is the patterning technology, which evaporates the OLED materials to the glass. Finally there's the encapsulation process which blocks out the outer moisture and air from the OLED elements. "For each of these technologies, LG has selected oxide TFT, WRGB OLED patterning and solid phase encapsulation."

OXIDE TFT

According to LG, oxide TFT offers several advantages over the other main method of backplane technolgy, LTPS (or low-temperature polycrystalline silicon). For instance, LTPS involves scanning the area over the TFT with excimer lasers, which is both very costly and time consuming. Laser scanning also makes it difficult to get a uniform level of luminance across the screen.

Oxide TFT, on the other hand, produces a higher luminance uniformity across the panel and is compatible with the company's current LCD production line, making it easier to produce a greater number of screens at a faster rate.

That's not to say oxide TFT doesn't present its own challenges, as LG said one key technical issue it had to overcome was obtaining a uniform threshold voltage. "To overcome this technical issue, we have improved our existing materials as well as adopted a new structure of TFT and a new manufacturing process that uses copper process and low temperature process," said Han.

"As a result, we have acquired a high level of uniformity in threshold voltage. Uniform level in threshold voltage means we can get a uniform level of electric current at a specific level of voltage, and it enables uniform luminance on the screen."

To prevent the threshold voltage from deteriorating over time and causing an imbalance in luminance, LG has also developed special circuit algorithms to sense any potential changes in the threshold voltage of each pixel. This will adjust luminance levels on a real-time basis, helping the panel last longer and prevent staining.

^ Since OLED doesn't require a backlight, it allows panels to be super slim

WRGB PATTERNING

For patterning its OLED panels, LG chose WRGB patterning over the more traditional FMM (fine metal mask) technology because of its higher yield rates and better overall performance. With FMM, the masks can become very thin over larger screen sizes, causing them to sag, making it tricky to deposit the OLED materials equally across the screen.

"To address the sagging issues, we could use smaller fine metal masks and scan above the glass," Han told us, "but it's still very hard to align several patterning masks for the exact deposition of OLED materials. So the productivity will be very low with the FMM method.

"Instead, WRGB patterning uses an open mask and deposits blue, green and red OLED by layer, not one by one. Therefore, with WRGB patterning, we can obtain a higher yield rate."

LG has also managed to lower the power consumption and increase the light output of its WRGB patterning method by using a newly developed two-stack structure of its materials. Previously, LG used a one-stack structure whose luminance efficiency was only 10 candelas per ampere. The company's two-stack structure, on the other hand, has increased this figure to 25cd/A.

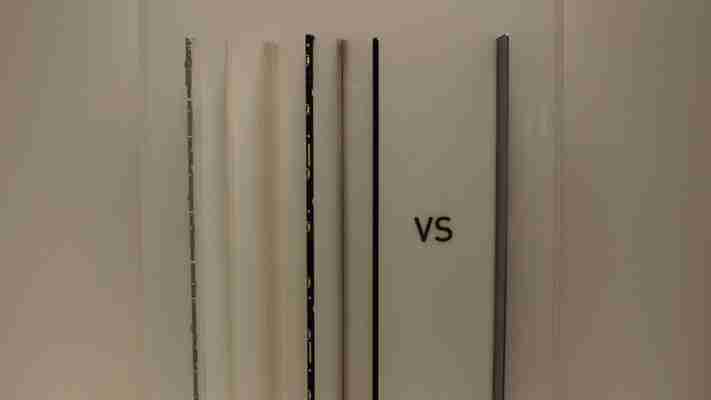

^ Making an LCD TV panel requires several more layers than OLED

SOLID PHASE ENCAPSULATION

As for LG's encapsulation process, Han said it had to develop its own solid phase technology in order to use it in curved and flexible displays. "We developed a high quality thin feel passivation structure that can be processed on a low temperature to minimise possible defects on the OLED display due to heat," he said.

"Unlike glass substrate, our unique metal substrate can realise a very thin and lightweight design. It's also more robust, which is perfect for curved and flexible displays."

This is particularly important, as LG believes that OLED is the best suited for curved TVs. "We are aware that there's a high level of interest for curved TVs," says Han. "While LCD has yet to fully overcome the viewing angle and light leakage issues, OLED TV, which does not have any liquid crystal and backlight unit, overcomes such issues."

^ Compared to other current (unnamed) curved LED TVs, LG's OLED set produced visibly richer, more accurate colours and didn't suffer from any light leakage when viewed at an angle

Don't hold your breath for a flat 4K OLED TV, though, as LG told us its primary focus for now is developing curved 4K displays. "Flat 4K OLED is something that we've not 100 per cent discontinued," said Robert Taylor, Product Manager for LG Electronics, "but the key message around OLED is that it's best for curved. We have the capability to make them curved and flat so depending on what the market demands, we might put a flat product into the line-up."

That's a shame as we're not entirely convinced by curved TV, especially for wall mounting, and feel that its introduction is as much a marketing differentiator for OLED than a practical neccesity.

OLED AND EYE FATIGUE

LG also believes that its WRGB patterning emits less blue light than LCD panels. This is part of the visible spectrum with prevalent blue-light ranges from 380nm to 550nm (around ISO 13,666) with high energy, and the measurements it's carried out so far suggest that LCD emits three times more blue light than its OLED panels, making them less comfortable to watch over long periods of time.

It's still a hypothesis at the moment, but LG's hoping to use these results as a foundation for future clinical tests to study how blue light affects eye fatigue.

OLED IN YOUR LIVING ROOM

LG still considers its OLED TVs a high-end, premium product, so it's unlikely that the price of these new sets will become much more affordable in the immediate future, but it's clear that OLED could be within our grasp sooner than we'd anticipated.

LG's new OLED panel factory, M2, which was completed this year, is now primed for large scale OLED production, with LG stating that it has capacity for 26,000 sheets a month compared to the 8,000 sheets capacity of its current OLED factory, M1.

"[OLED TV] is probably our biggest agenda," said Andrew Mackay, Commercial Director for LG Electronics. "In the last ten years [...] OLED has allowed us to become more aspirational and premium as a brand, [and] that's beginning to be recognised. LG is a more design premium, high-equity brand than it used to be, and I think OLED will be key within that."

Leave a Reply